Education

Education Solutions

fischertechnik Education is dedicated to supporting STEM education. They offer hands-on solutions for learners of all ages, from kindergarten and elementary, through middle & high school, right on up to college & university, and even industry. Students are able to develop a deep understanding of how devices and mechanisms work.

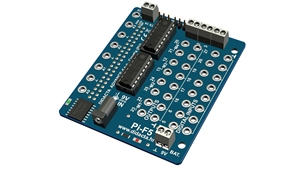

fischertechnik Raspberry PI-F5

The Pi-F5-HAT is a fischertechnik adapter for the Raspberry PI. The Pi-F5-HAT can be used to control DC and SERVO motors as well as digital and analogue sensors. With the programming language of your choice (Python, C, Scratch, ...), the Hat can be managed in such a way that no special libraries are required. It is possible to work simultaneously with 4 DC motors bidirectionally and 2 SERVO motors (microservo 4.8V / 6V). The number of motors that can work simultaneously depends on the power supply connected to the Pi-F5-HAT (e.g. fischertechnik power supply 9V / 2.5A). The Pi-F5-HAT and the Raspberry PI together can also be supplied with power by a 9V power supply unit or a fischertechnik battery (1800 mAh). The output voltage which supplies the DC motors corresponds approximately to the input supply voltage of the Pi-F5-HAT (9 V). the HAT also supports the operation of all fischertechnik DC motors (S motor, XS, XM, encoder motor).

Maker Kit Bionic

Create your own walking robot with our flexible base!

Top Features

- The Maker Kit Bionic enables you to create your own walking robot with a flexible basis.

- The supplied 3D data for common developer boards makes it easy to integrate additional components.

- Simple expansion options.

- Included are 8 servo motors with fischertechnik mounts and a walking robot chassis with a flat platform for your own superstructures.

- Includes 161 parts for building one model.

- Recommended for age 14 and above.

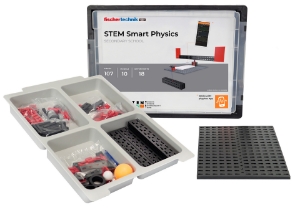

STEM Smart Physics

The world of construction and data analysis combined

STEM Optics

Explore the basic principles of optics in a playful and interactive way

Robotics Add-On: AI

Explore the future technology!

Combined with the ROBOTICS TXT 4.0 Base Set (required), this set allows you to build 3 AI focused models.

Components: 314

Experiments: 6

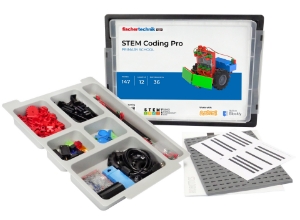

STEM Coding Pro (No Battery)

Learn hands-on programming, computer science, and robotics fundamentals in primary school with Robotics STEM Coding Pro.

STEM Coding Competitions

The all-in-one set for successful competition participation

- Specially developed for competitions

- TXT 4.0 Controller included

- Recharegable battery pack and charging unit

- Kit for individual chassis

ROBOTICS STEM Coding Pro

Learn programming hands-on in primary school

Practice Scratch programming and learn how to operate the user-friendly controller

Understand the way actuators and sensors work

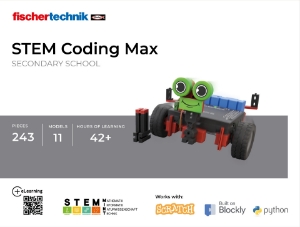

STEM Coding Max

Hands-on and problem-based construction and programming in secondary school

- Explore and perform everyday tasks in Information Technology and Robotics

- Learning block-and text-based programming for an easy-to-use controller

- 11+4 models

- 42+ Hours of Learning

- 2-4 students

- Requires 9v battery—not included

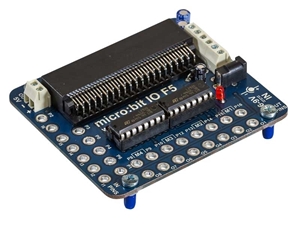

fischertechnik micro:bit F5 Adapter

Specially designed adapter to bridge the gap between the micro:bit controller and the versatile fischeretchnik modular system. The adapter board has 8 outputs and 6 inputs.

CLASS SET Basics

Foster creativity with the class set for elementary school

- Included building ideas allow an easy introduction to first constructions

- Building ideas for inspiration

- Creative building

- Colourful building blocks and figure for role play

- Encourage creativity and hand-to-eye coordination

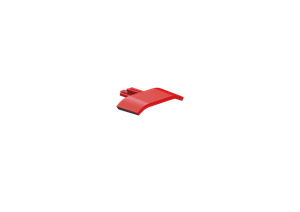

Storage and Transport Case

For safe storage and transport of fischertechnik Factory Simulation and Training Factory Industry 4.0 models

Advantages:

- A practical custom case for safe storage and transport of fischertechnik factory models

- Insert once - done! The lower part of the factory is fully functional, only the hood has to be moved.

- Inside lined with soft foam padding

- 3 inside zipper pockets for stowing accessories

- 4 tiltable carrying handles

Training Factory Industry 4.0 – 9V version 2

Digitalized training and simulation model for Industry 4.0 applications

- Training and simulation on a realistic production model, in-depth learning through haptic understanding

- Optical and sensory applications, digital traceability with NFC/RFID

- Integrated cloud connection, control via smart devices, as well as use and operation of dashboards

- Remote monitoring via camera possible as well as linking of production and scheduling data

- Connection of upstream/downstream logistics processes

6-Axis Robot 9V

- Coding of a multi-axis robot

- Can be equipped with both a vacuum suction cup and a gripper

- Position determination via 6 axes

- Three of the six axes are controlled with encoder motors, three others with digital servos

- Programming can be done either via Python or ROBO Pro Coding

APS ADD ON: Automated Guided Vehicle

Ideal add-on for expanding the capabilities of the Agile Production Simualtion Model

The APS Add On: Automated guided vehicle system extends the Agile Production Simulation (APS) with an additional automated guided vehicle system (AGV). This is responsible for intralogistics within APS and enables agile and flexible processes. The additional AGV significantly increases the possibilities of intralogistics. Parallelization and prioritization in the production workflow can be planned, tested and experienced. At the same time, the complexity of logistics processes increases.